The most widely used field of sterile isolators is in the pharmaceutical industry, because the research and production process of drugs needs to add a layer of physical barriers to isolate the operator and the sterile production environment to protect the product from contamination.

Clean Room Positive Isolator Pharma for Sterility Testing Supplier

The most widely used field of sterile isolators is in the pharmaceutical industry, because the research and production process of drugs needs to add a layer of physical barriers to isolate the operator and the sterile production environment to protect the product from contamination.

Common processes such as packing, weighing, batching, crushing, sampling, etc., can be carried out in positive pressure aseptic isolators.

The compounding aseptic containment isolator is generally used in combination with the operation module and the transfer module, or can be used alone. The design and flow direction of the air flow is very similar to that of the biosafety cabinet, the difference is that the isolator cabinet is in a positive pressure fully closed state, the secondary biosafety cabinet is a negative pressure semi-closed, and the third-level biosafety cabinet is a negative pressure fully closed, which is determined by the functions of the two.

Isolators can be large or small, and the function and scale are mostly customized according to user needs. In the process of use, the operating samples and equipment enter the operating compartment through the transfer compartment and close the transfer compartment door, and the experimental personnel operate through gloves.

VHP isolator, mainly for aseptic production, detection of two major applications. VHP sterilization system can be configured according to customer requirements. The closed isolator is mainly used to completely separate the personnel and the production process in the operation process to avoid contamination or cross-contamination of the product. Sterility inspection and microbial inspection to ensure the authenticity of test results and protect the safety of operators, the main structure of the cabin body is stainless steel and tempered glass, hard cabin structure, air flow model for laminar flow or turbulence, static is in line with class A standards.

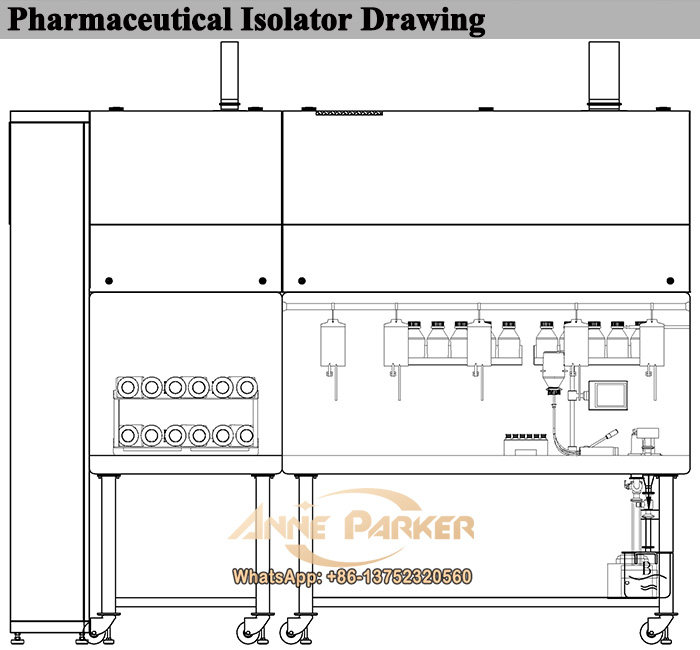

Technical parameters

|

Model |

AN-ISO2050(S2) |

AN-ISO2450(S3) |

AN-ISO3150(S4) |

AN-ISO3150(W8) |

|

Dimensions |

2050*850*2480 |

2450*850*2480 |

3150*850*2480 |

3150*1100*2480 |

|

Glove station |

2 Gloves |

3 Gloves |

4 Gloves |

8 Gloves |

|

Air distribution |

Air flow |

|||

|

Cabin body tightness |

It meets the requirements of ISO10648-2 standard and meets the requirements of EU and FDA regulations |

|||

|

Gate system |

interlock system |

|||

|

Filter |

G4 primary filter + H14 HEPA filter |

|||

|

Control system |

PLC intelligent control system (industrial PC computer, Siemens S7-1200PLC, three-level authority, e-signature, audit trial) |

|||

|

Intelligent monitoring |

Isolator cavity pressure difference / HEPA filter pressure difference / Wind speed on the outlet side / Leakage rate per hour / gas concentration / humiture |

|||

|

Pressure detection |

±80Pa |

|||

|

System Integration |

Humiture / wind speed / Hydrogen peroxide concentration / On-line monitoring of particles and planktonic bacteria |

|||

|

Leakage rate per hour |

<0.5% Vol/hr |

|||

|

Power demand |

220V/5KW |

|||

Prefernces

1. The inner cavity adopts laminar (turbulent) air supply, and the air manifold is professionally designed to ensure the purification level;

2. Real-time monitoring of the chamber pressure, temperature, wind speed, and automatic control and adjustment;

3. It can integrate LOG sterilization program, and the killing rate of microorganisms can reach more than 6 Log levels (Log 6);

4. The sealing grade of isolator is tested in strict accordance with IS014644-2 standard;

5. The waste can be quickly transmitted from the working area through RTP and aβ valves to ensure the internal environment of the isolator is clean (optional);

6.PLC control, touch screen operation, key operation interlock control, effectively prevent misoperation;

7. Real-time monitoring of key parameters, easy export and printing of stored data and charts;

8. Can integrate dust particle online detection system, plankton online sampling system and hydrogen peroxide concentration online detection system according to needs;

9. Can be equipped with a leak detector in gloves;

10. The product can be customized according to customer needs.

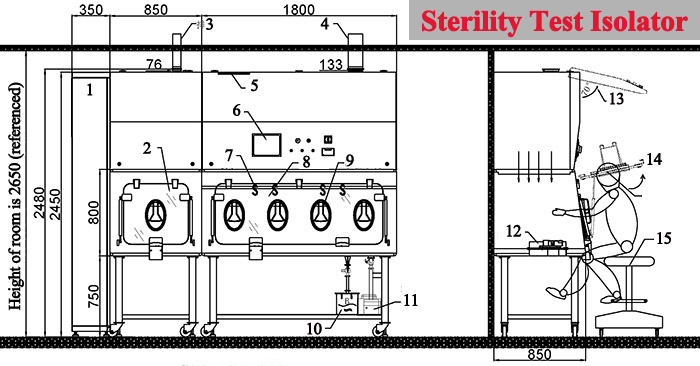

1. Electrical control cabinet 2. Transfer chamber 3. Exhaust outlet (outside) 4. Exhaust outlet (outside) 5. Fresh air filter (room fresh air) 6. Control panel 7. 10 movable hooks 8. Operating chamber 9. Glove system 10. Waste liquid treatment (10L) 11. Particle monitoring system. The vacuum pump is placed in the electrical control cabinet 12. Bacterial collection instrument 13. Maintenance space 14. Wing-shaped lifting 15. Sitting posture operation 16. Suspended frame 17. Reserved position for waste liquid outlet 18. Transfer door opening size 400×400 19. Bacterial collection instrument 20. Suspended particle sampler 21. Online particle monitoring 22. Auxiliary operation position 23. Main operation position

|

Technical Parameters |

|||

|

Temperature |

18°~26° |

Exhaust air rate |

≈850m³/h |

|

Humidity |

45%-80% |

Exhaust air interface |

∅76/∅133 |

|

Total power |

4.5KW |

Air intake and exhaust efficiency |

H14 |

|

Voltage |

220V |

Weight |

1000kg |

|

Frequency |

50HZ |

Compressed air pressure |

0.6~0.8MPa |

|

Transfer chamber size |

External dimensions: W850mm×D850mm×H2480mm; Internal dimensions: W830mm×650mm×700mm |

||

|

Operating chamber size |

External dimensions: W1800mm×D850mm×H2480mm; Internal dimensions: W1780mm×D650mm×H700mm |

||

|

Configuration Table |

||

|

No. |

Part Name |

Description |

|

1 |

Control system |

Siemens PLC S7-1200 |

|

2 |

Touch screen |

Yinchi 10 inches PC screen |

|

3 |

High-concentration probe |

Vaisala Three-in-One Probe (operating chamber) |

|

4 |

Air supply / exhaust motor |

EBM/XM/AFL brand |

|

5 |

Air supply filter |

Efficiency: 99.995% H14 (Anne Parker brand) |

|

6 |

Exhaust filter |

Efficiency: 99.995% H14 (Anne Parker brand) |

|

7 |

Bacterial collection instrument |

STERT86 Jivo brand |

|

8 |

Air velocity transducer |

CTV114 KIMO brand |

|

9 |

Micro differential pressure sensor |

Dwyer brand |

|

10 |

VHP flash distillation plant |

FEV-001 (Anne Parker brand) |

|

11 |

Pneumatic control unit |

AirTAC brand |

|

12 |

Glove system (8-inch oval shape) |

Integrated(North / Piercan usa / RotAdler brand) |

|

13 |

Online particle monitoring system |

Remote (lighthouse brand) |

|

14 |

Temperature / humidity sensor |

Brand: ROTRONIC / Vaisala (transfer chamber) |

|

15 |

Printer |

Model: WH-E34/36, brand: Weihuang |