|

|

|

|

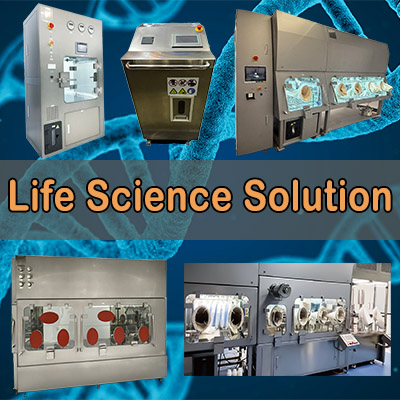

Anne Parker produces VHP pass boxes, VHP generators, aseptic inspection isolators, negative pressure isolators, and other cleanroom equipment mainly used in life science laboratories. These clean room products help your life science laboratory achieve the required cleanliness level. High-end customized VHP series cleanroom products can be delivered within one week. Cleanroom equipment of Anne Parker are the ideal choice for you when it comes to cost-effective clean room products. If you currently have any related clean room projects & equipments that require our clean room equipment, we sincerely welcome your inquiry!

Biopharmaceuticals are regarded as one of the core elements of the world's knowledge economy in the 21st century and have become a new trend in the pharmaceutical industry. As an industry with high demand, high technology, high investment, long cycle and high risks, the requirements for air cleanliness in the production area are extremely strict. Air cleanliness directly affects the quality and grade of the final medicine.

In order to ensure that the cleanroom projects and equipments quality can be effectively controlled and objectively evaluated in a timely manner, and to guarantee that the production environment meets the requirements, Anne Parker has launched a digital cleanroom overall solution for biopharmaceuticals. This solution features low energy consumption, high efficiency, and visualization, and can achieve integrated optimization management of the "inspection - control - monitoring" full chain. It covers one-stop products such as real-time dynamic monitoring systems for particles and suspended bacteria in cleanrooms, environmental detection instruments for cleanrooms, air filters, and air purification devices, as well as third-party testing services. This ensures that the production environment complies with relevant standard requirements.

This solution of clean room projects & equipments is specifically designed for implementing quality risk control in the field of sterile pharmaceuticals and for dynamic environmental monitoring throughout the entire sterile production process. It can effectively remove particulates and bacteria from the air, and can simultaneously monitor environmental parameters such as dust particles, airborne bacteria, pressure difference, temperature and humidity, wind speed, etc. It can promptly grasp the trend of air cleanliness changes and take measures in advance to eliminate possible adverse operations, pollution sources and pollution incidents, thereby safeguarding the pharmaceutical production process.