The dynamic pass through box is the auxiliary device to the clean room. It is used to transfer small objects between clean rooms and non-clean rooms, so as to reduce the frequency of opening the doors and the pollution of the clean room can be reduced to a minimum.

Cleanroom Dynamic Pass through Box for Microbiology Lab

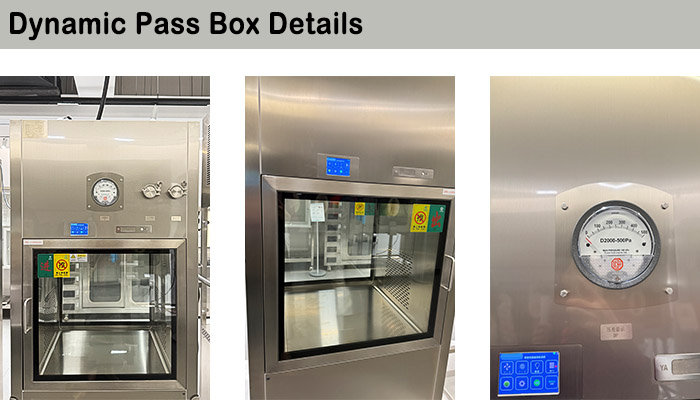

Ultraviolet light is installed in the dynamic pass through box, and the articles are sterilized by ultraviolet light before entering the clean area for microbiology lab. On the one hand, it plays the role of an airlock to prevent the high pressure in the high-level clean room from being leaked, and on the other hand, it realizes the self-purification effect during the re-transmission process to ensure the self-cleanliness of the items entering the clean area and reduce the cross-contamination brought by the objects.

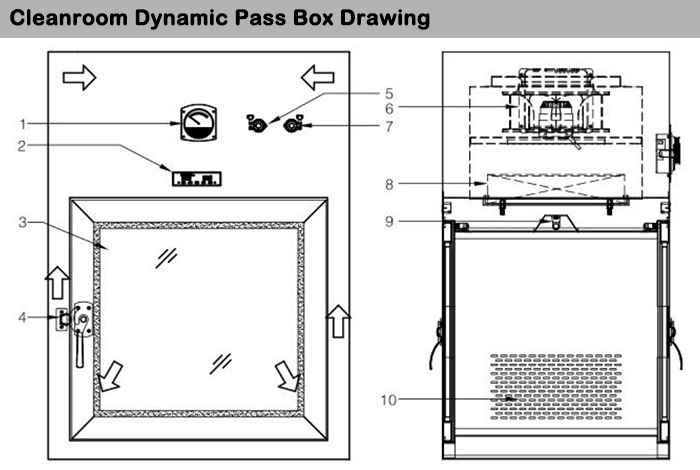

1. Pressure differential gauge 2. Centralized control panel 3. Double toughened glass door 4. Stainless steel meniscus handle 5. DOP test port 6. Centrifugal blower 7. PAO sprue 8. Gel seal HEPA filter 9. UV light sterilizer 10. Return air mesh plate

Pass box for microbiology lab Technical Parameters

|

Model |

External dimension (mm) |

Work area size(mm) |

Filter size (mm) |

Wind speed (m/s) |

Cleanliness class |

Noise (dB) |

Shower time (min) |

Power (KW) |

|

AN-CLCDC 400 |

600*470*1000 |

400*400*400 |

230*180*90 |

0.45±20% |

Class A |

65 |

Manually adjustable (0~999) |

0.2 |

|

AN-CLCDC 500 |

700*570*1100 |

500*500*500 |

330*280*90 |

0.3 |

||||

|

AN-CLCDC 600 |

800*670*1200 |

600*600*600 |

430*380*90 |

0.4 |

||||

|

AN-CLCDC 800 |

1000*870*1400 |

800*800*800 |

630*580*90 |

0.6 |

Note: The specifications listed in the table are for customer reference only. cleanroom dynamic pass box can be designed and made according to customers' requirements.

Basic performance requirements of pass box for microbiology lab:

1. Cleanliness requirements in cleanroom dynamic pass box Class A;

2. Double shell inside and outside, circular arc treatment around the inside to ensure seamless connection;

3. Adopts laminar flow design, the air flow direction adopts the mode of up and down, the bottom adopts 304 stainless steel cold-rolled plate punching design, and the reinforcement is set;

4. Filter: the primary efficiency filter is G4, the HEPA filter is H14;

5. Wind speed: After the HEPA filter, the outlet wind speed is controlled at 0.36-0.54m/s (tested at 150mm below the HEPA outlet flow average plate);

6. Differential pressure function: display filter differential pressure (range efficiency 0-500Pa/ medium efficiency 0-250Pa), accuracy ±5Pa;

7. Control function: blower start/stop button, equipped with built-in electronic door interlock; Set UV lamp and design with separate switch;

8. The access port is set at the lower part of the cleanroom dynamic pass box for the maintenance of the blower;

9. Noise: Noise < 65db during normal operation of the pass box clean room;

10. Efficient air flow distribution plate: using 304 stainless steel mesh plate.